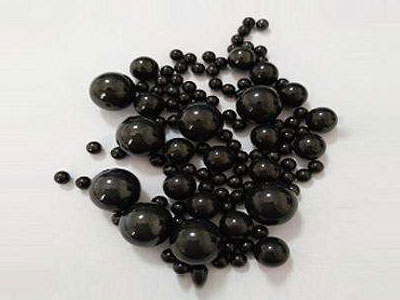

Grinding medias

The materials and sizes of the grinding media of your equipment can be selected according to the different characteristics and requirements of the abrasive materials to achieve various results. For example, large size of grinding medias are suitable for grinding larger particles or denser structure, while small size of grinding medias have effect on smaller particles, it can make smaller particles even smaller.

With professional grinding knowledge and rich experience, our engineers will discuss matters w with you in detail, taking your entire production process into consideration to help you select the right grinding media according to your production process and requirements.

We offer high quality grinding media to meet the most demanding needs of our customers. Here we show several grinding media. Please feel free to contact us for more information or technical support.

-

- Zirconia

- Featuring high hardness, high strength and low abrasion, zirconia is mainly used for ultrafine grinding and dispersion of high-viscosity and high-strength materials requiring for “zero pollution”.

- Zirconia

-

- Stainless steel bead

- The hardened and tempered stainless steel bead provides good hardness, and it has good corrosion resistance due to the smooth surface. Therefore, it can be widely used for grinding materials such as graphite and paint which are not too hard.

- Stainless steel bead

-

- Chrome beads

- Chrome beads with good hardness and wear resistance are often used for grinding ultra-high hardness materials.

- Chrome beads

-

- Alumina

- Alumina with good mechanical properties and wear resistance can be utilized in grinding abrasive materials requiring high fineness such as inks, paints, ceramic materials and the like.

- Alumina

-

- Silicon carbide

- Silicon carbide is adopted to grind silicon carbide materials to avoid contamination by other materials. We offer different sizes of silicon carbide abrasive materials.

- Silicon carbide

-

- Silicon nitride

- Silicon nitride is used to grind silicon nitride materials to avoid contamination by other materials. We offer different sizes of silicon carbide abrasive materials.

- Silicon nitride

-

- Tungsten-carbide ball

- With good corrosion resistance, abrasive resistance, and crushability on hard and brittle materials like metals and minerals, tungsten-carbide ball can realize better grinding of materials, and stirring and mixing of high-viscosity liquid.

- Tungsten-carbide ball

Request a Quote? Feel free to contact us at any time!

click here